Since 1999, smARTSOL Ltd. has been a major player in the domestic and international industry. Over the years, our company has continuously developed its technology and services to provide our customers with the highest quality, customized solutions. We also have outstanding expertise in the field of machining metal structures. Whether it is sheet metal, shaped iron, tubes or rectangular tubes, we have the right solution for every need.

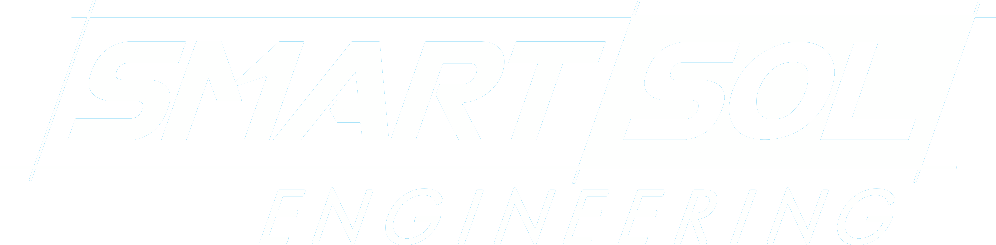

Sheet metal working

Machining of tubes, pipes, profiles

Assembly of welded structures

Tube bending

Sheet metal and tube/pipe laser cutter

NC-controlled, hydraulic pipe bending machine

Maximum tube dimensions: 65x3x3500mm

Maximum bending radius: 250mm

Maximum bending angle: 190°

Laser welding and cleaning machine

1500W power

Weldable materials: steel, stainless steel, aluminium and copper

Welding without filling material is also possible

Automatic wire feed

Multiple welding seam patterns

The equipment can also be used for laser surface cleaning, which significantly facilitates the removal of rust in the case of complex parts, for example.

Other welding processes

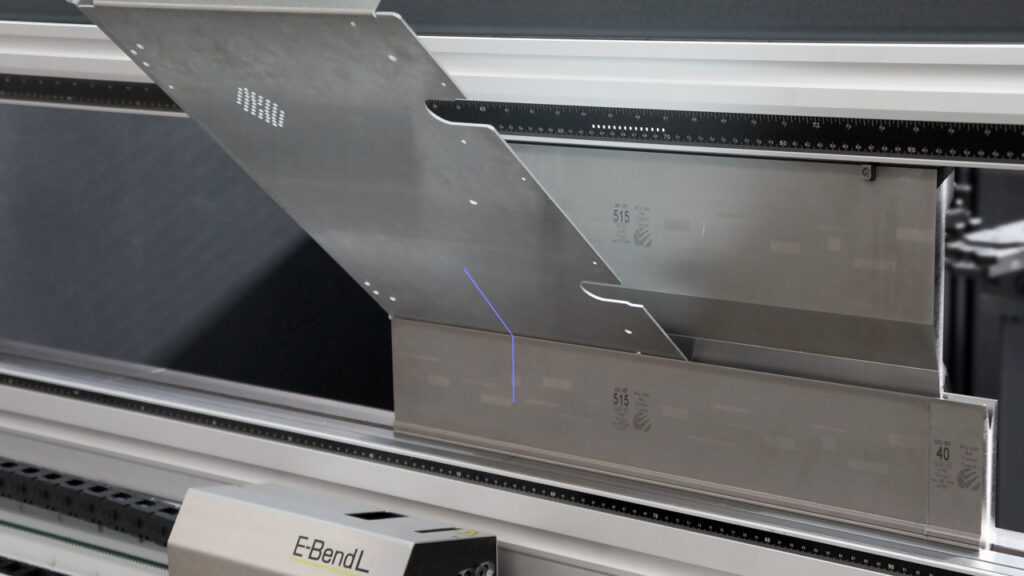

DEMMELER assembly system

Maximum pressing force: 80t

Flat bar max. thickness: 300×20 mm

Flat bar max. width: 450×15 mm

Profile cutter, 90° cut: 130x130x13 mm

Profile cutter, 45° cut: 70x70x7 mm

Circle rod: 45 mm

Square rod: 45 mm

U-profile: 140 mm

T-profile: 60 mm

I-profile: 140

Sheet metal punch max. thickness: 12 mm

In addition to our own stock of raw materials, we can obtain commonly used raw materials and qualities from our reliable and permanent supplier partners from stock or at short notice.

The above material qualities can also be processed in the form of flat sheets, pipes and various profiles.

miklos.makai@smartsol.hu

+36 30 970 6040

andras.makai@smartsol.hu

+36 30 444 7659

Don’t miss the latest news and offers!

Contact Us

Where to find us?

Copyright 2020-2024 smARTSOL.

All rights reserved.

The use of this website requires the acceptance of our Privacy Policy.