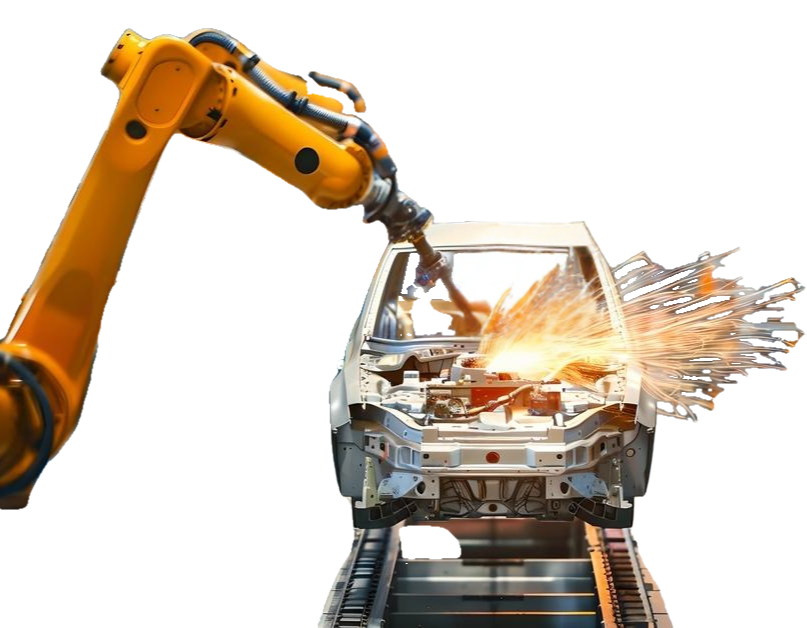

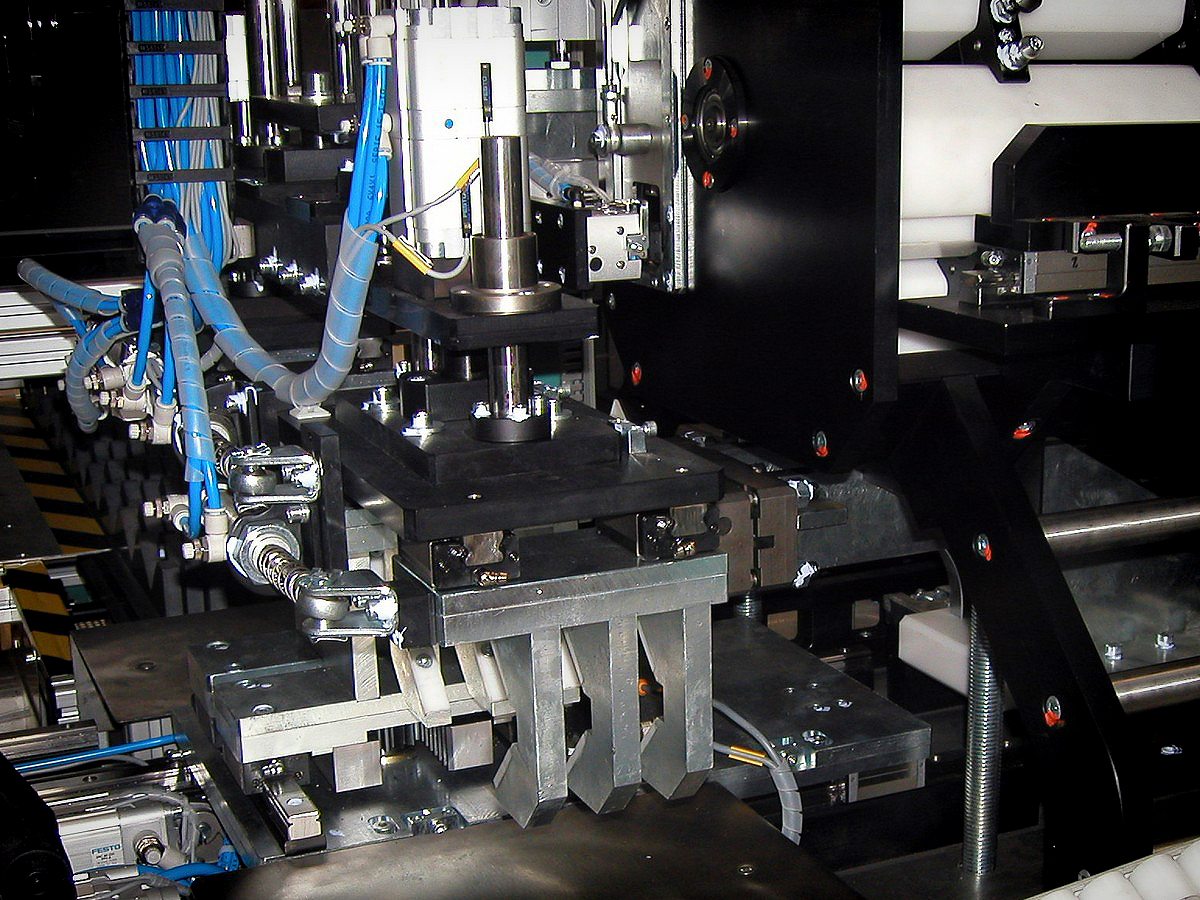

Robotcelláink optimálisan illeszkednek az adott feladathoz (pl. hegesztés, festés, nyomtatás, összeszerelés) és a rendelkezésre álló helyhez.

Ipari szektortól függetlenül egyedi automatizálással és moduláris rendszerekkel valósítjuk meg elképzeléseit: robotkarok (pl. Fanuc, KUKA), perifériák, vezérlőszoftverek. Ipari tanácsadással és karbantartással foglalkozunk.

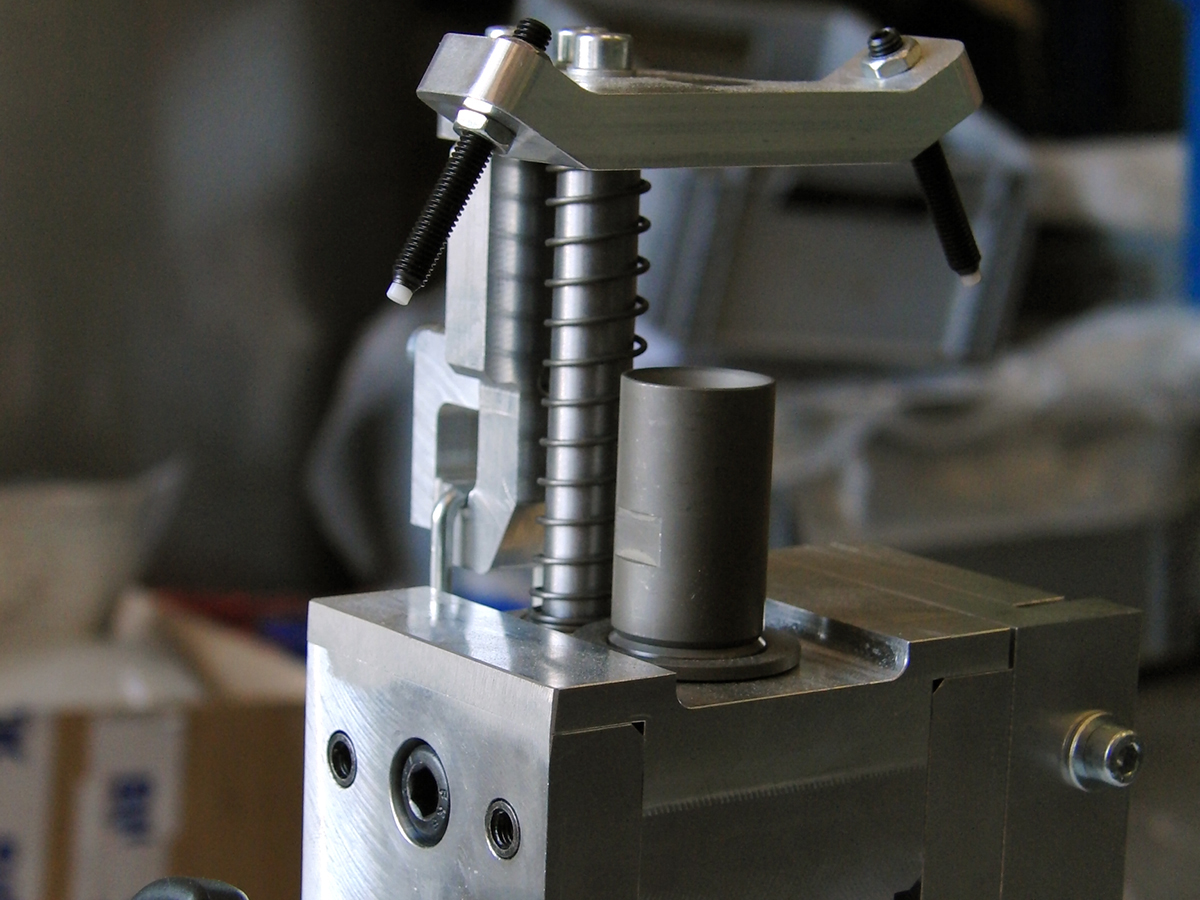

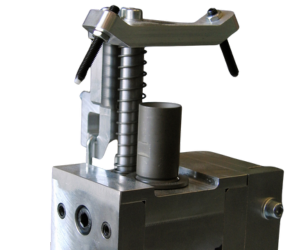

A smARTSOL-nál komplex és intelligens megoldásokat integrálunk, hogy megtervezzük, legyártjuk, összeszereljük és beállítjuk az Ön által elképzelt és meghatározott egyedi gyártókészülékeket,

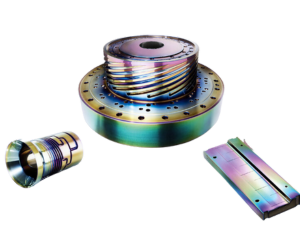

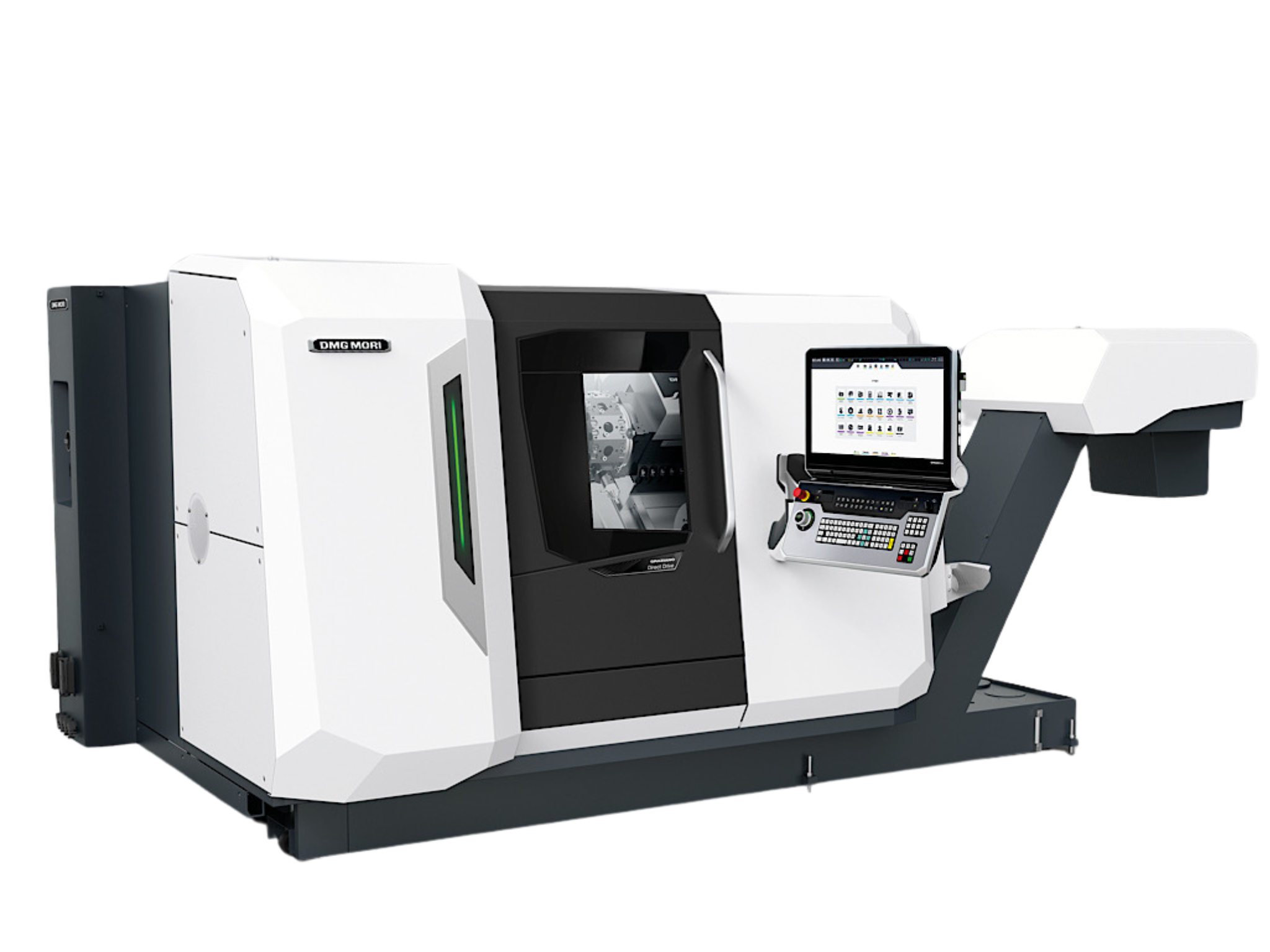

Széleskörű és változatos CNC gépparkunk lehetővé teszi a legbonyolultabb alkatrészek gyártását is rövid ciklusidők mellett:

Az általunk feldolgozott anyagok széles skálán mozognak, a szerszámacéltól a nagy ötvözetű alumíniumokig, és magukban foglalják az ipari műanyagok és kompozitok széles választékát.

Cégünket 1999 januárjában alapítottam, több évtizedes gépészeti hagyományokra építve. A 100%-ban magyar tulajdonú családi vállalkozás fő célja, hogy teljes mértékben kielégítse partnereink igényeit a gépészet, az ipari automatizálás és a precíziós alkatrészgyártás területén.

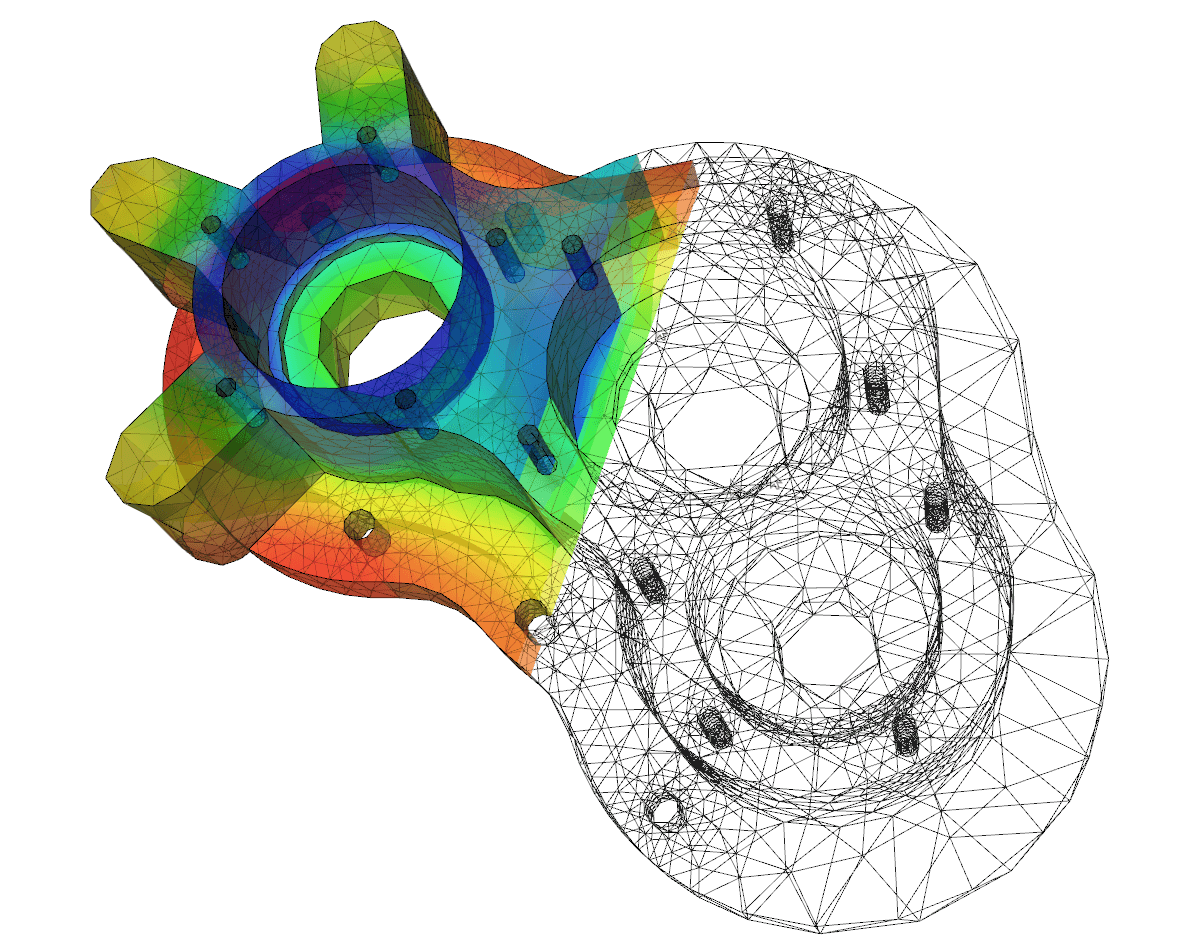

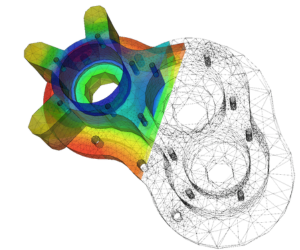

A smARTSOL Engineering Kft. mechanikai és technológiai megoldásokat kínál az iparnak mind Magyarországon, mind külföldön. Tapasztalt mérnöki csapatunk modern 3D CAD-CAM-CAE tervezési környezetben végzi el ránk bízott tervezési feladatokat.

Saját humán és technológiai erőforrásaink – mint például képzett szakembereink, precíziós CNC berendezéseink, a CMM mérőberendezéssel támogatott minőségbiztosítási rendszerünk és az integrált vállalatirányítási rendszerünk – garantálják a kiváló termékminőséget.

Ipari ágazatok: autóipar, repülőgépipar, orvosi műszergyártás, gyógyszeripar, élelmiszeripar, energiaipar, műanyagipar, elektronikai ipar.

Makai Miklós

(Ügyvezető, fejlesztőmérnök)